Contract development

Stemmatters provides product, process, and analytical methods development and validation services tailored to each client’s specific requirements.

Taking a therapeutic asset from discovery to market is a complex challenge for any organisation, and cell and tissue-based biologicals face additional barriers.

Building a comprehensive evidence-base around product characterisation is essential to optimize your assets for strong clinical performance and successful market authorisation.

Stemmatters supports the design and definition of product specifications to build a well-defined and controlled product that can be consistently manufactured.

Stemmatters is able to contribute formulation development, stability studies, biocompatibility studies, and other IND-enabling studies to optimise the product profile for clinical evaluation and commercial success.

We have a strong track record of seamless technology transfer procedures, assuring the ability to validate your optimised solutions in-house.

Engineering a robust, scalable and reproducible manufacturing process is a challenging task.

Process development should ensure full cGMP compliance, remove extraneous handling steps, optimise cost-of-goods, while providing adequate scalability to serve foreseen commercial demand.

Crucially for cell and tissue products, manufacturing processes should be established in such a way that major alterations are not required in late-stage clinical development, which could undermine product’s viability.

Stemmatters specialises in taking early-stage product processes through to commercially relevant and scalable manufacturing processes.

Stemmatters critically reviews bench-scale processes and transforms them into validated, cGMP-compliant operations capable of meeting commercial-scale production, while maintaining product specifications and ensuring legacy batch comparability.

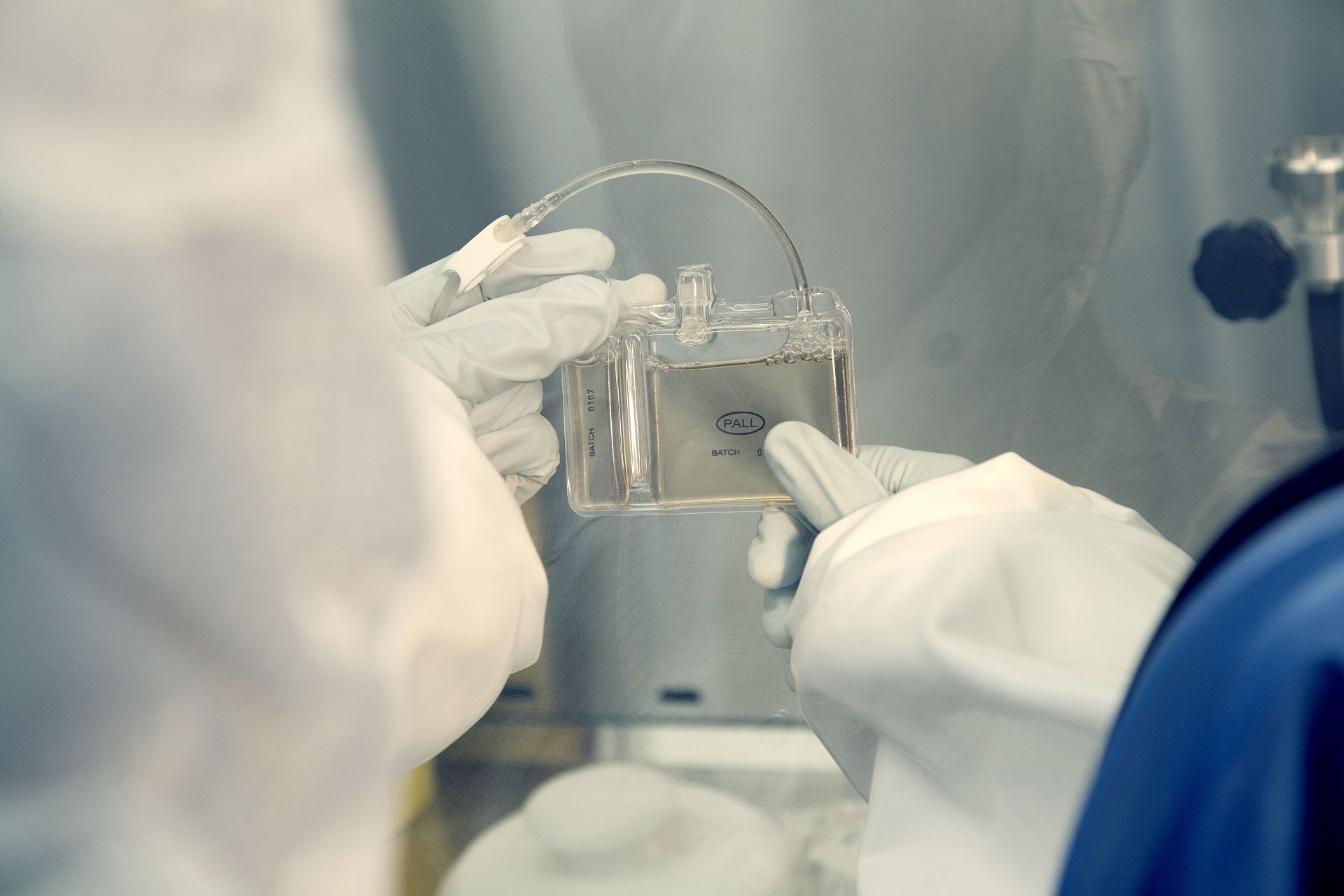

We have a successful track record of designing, optimising and validating single use closed processes that deliver the specified product profile, maintaining quality attributes for products used in non-clinical and clinical applications.

Robust and validated product and process analytics are at the heart of product quality programmes.

Refining product specifications usually requires the development or application of additional analytical procedures, either to improve analytical capabilities, or for the addition of new ones.

The quality programme of a product requires well-defined and robust specification parameters, in addition to regulatory compliance. Moreover, potency assays that accurately reflect the product’s mechanism of action may need to be established.

In addition to product characterisation, process analytical technologies can also be implemented to measure and control manufacturing processes further upstream.

Stemmatters understands the critical importance of the analytical framework, and offers a variety of analytical development and implementation services, both for products and processes, to ensure quality and purity of products according to GMP guidelines, including methods to assess product stability and support end-product release.